Aluminum Gravity Die Casting Services in Gujarat, India

At Evocative Industries, we offer premium Aluminum Gravity Die Casting services in Gujarat, India, catering to diverse sectors like automotive, EV components, defense, electronics, appliances, and industrial equipment. Our foundry near Ahmedabad is equipped to produce high-quality, precision gravity die cast aluminium parts that meet the stringent demands of modern industry.

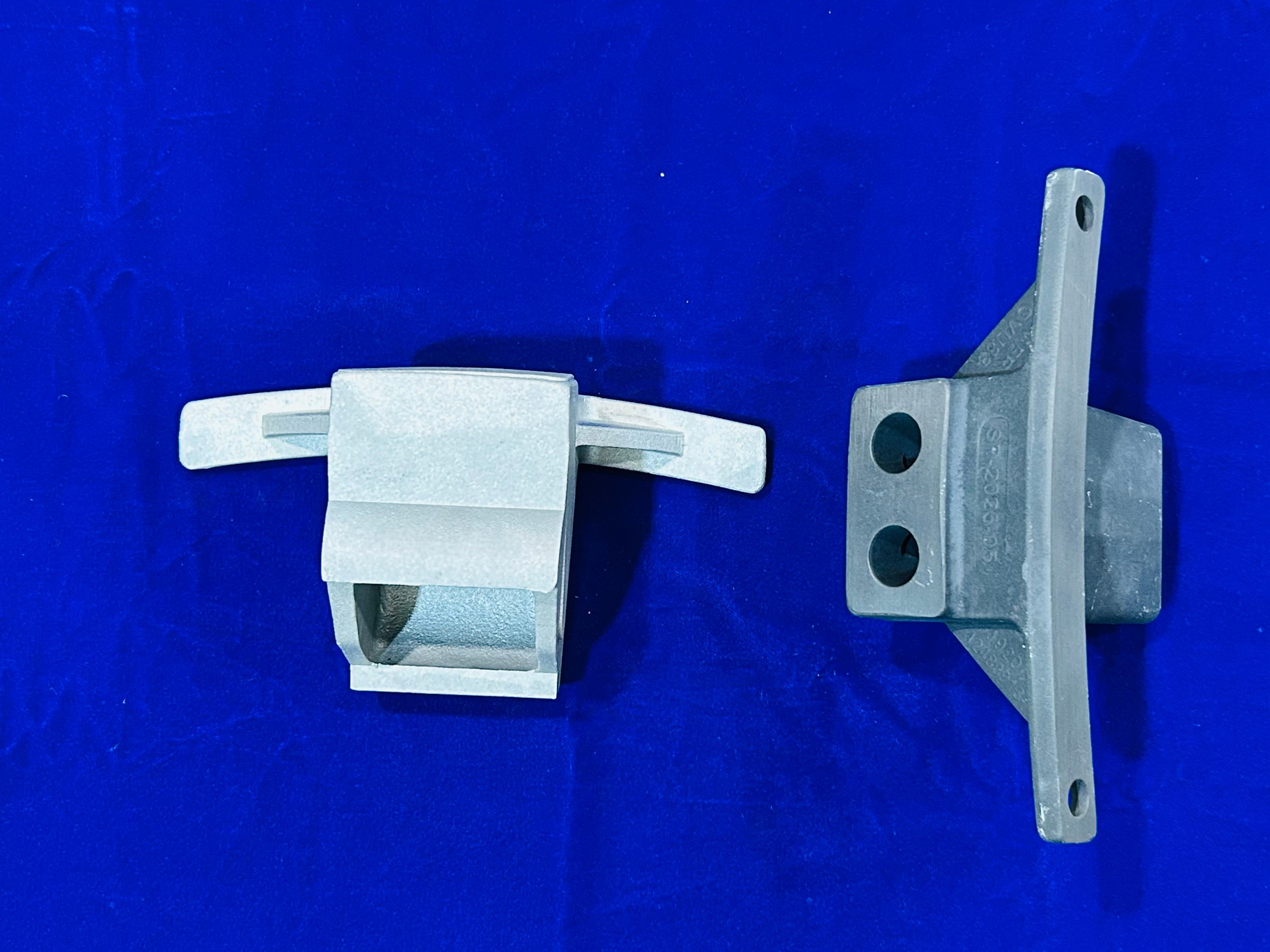

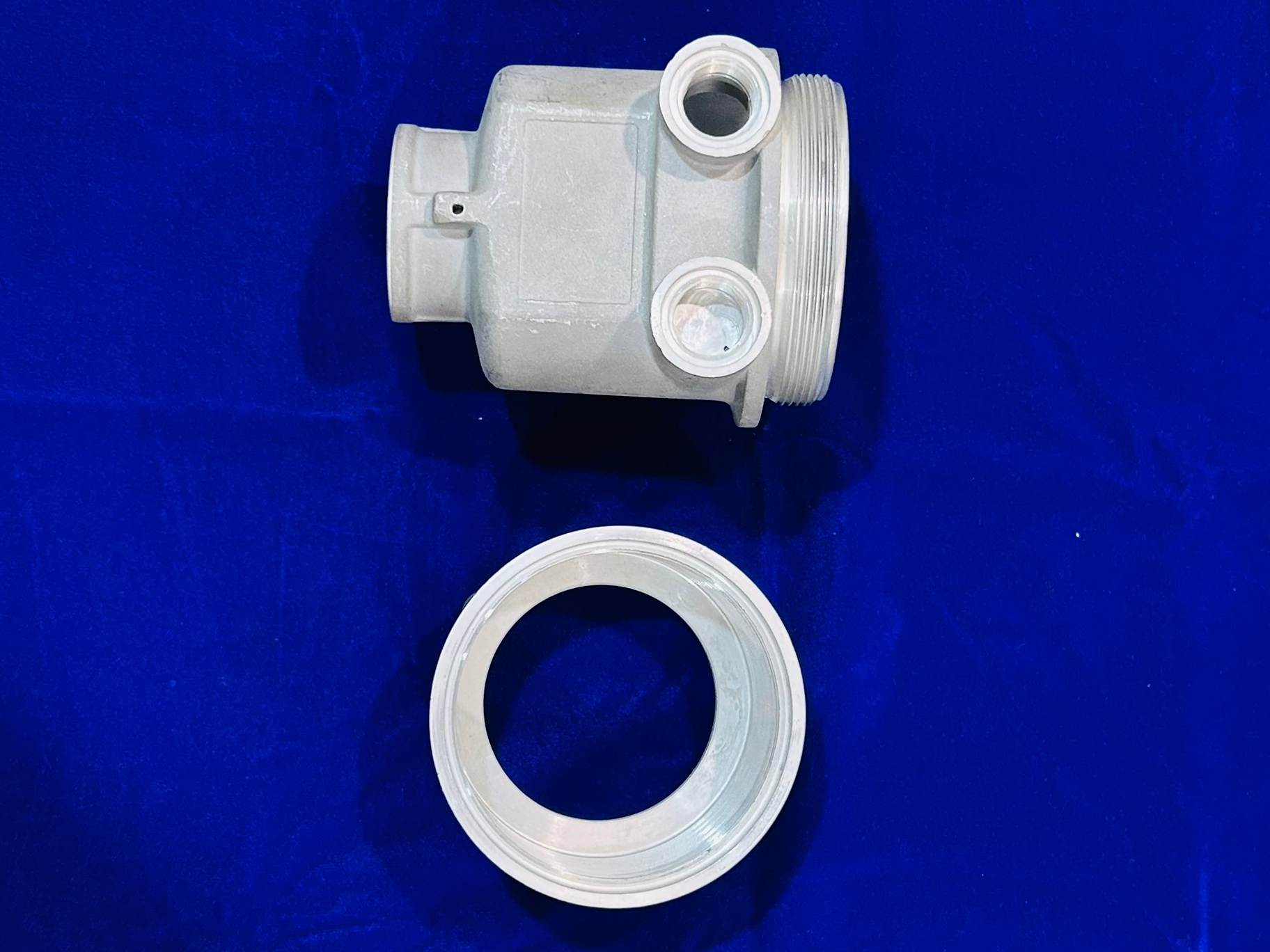

Our aluminum gravity die casting process utilizes advanced technologies and robust, reusable steel molds to deliver complex aluminium castings with excellent mechanical strength, fine surface finish, and minimal porosity. This makes our solutions ideal for automotive engine brackets, transmission covers, EV battery housings, and aerospace structures. We follow strict quality control protocols to ensure each component aligns with international standards.

One of the major advantages of gravity casting services is the ability to create parts with consistent dimensional accuracy, reduced defects, and reliable repeatability throughout production runs. Whether you need bespoke aluminium casting services, tailored aluminium die casting for prototypes or small batch casting, our team is ready to deliver solutions that match your specifications and volume requirements.

We specialize in serving both high-volume manufacturers and growing businesses requiring custom aluminium gravity die casting and precision industrial casting services. Our expertise extends to defense component casting, electronics die casting, and appliance castings, and we can accommodate complex geometries and special alloy formulations for specialized applications.

Our services include full assistance from design optimization, mold fabrication, casting production, and post-casting processes, such as CNC machining, shot blasting, powder coating, anodizing, and final inspection. This ensures that every aluminium gravity die cast part not only meets functional requirements but also passes aesthetic and durability expectations. As a reliable gravity die casting partner in Gujarat, we support clients in Ahmedabad, Vadodara, Rajkot, Surat, Gandhinagar, and across India.

What is Gravity Die Casting?

Gravity die casting (also known as permanent mold casting) involves pouring molten aluminum into reusable steel or iron molds without external pressure. The controlled filling process ensures better grain structure and mechanical properties compared to sand casting, making it a preferred choice for parts that require strength, leak resistance, and high accuracy.

- Custom Permanent Mold Design: We develop long-life metal dies tailored to client specifications for consistent production.

- Material Expertise: Skilled in casting popular aluminum alloys such as LM6, LM9, and LM25 based on application requirements.

- Superior Metallurgical Properties: Fine grain structures and low porosity suitable for load-bearing and high-performance parts.

- Post-Casting Processes: In-house machining, heat treatment, and finishing options available for turnkey solutions.

- Cost-Effective Production: Efficient for medium quantities with excellent repeatability and reduced tooling costs over time.

Key Features & Capabilities

Applications

Our aluminum gravity die casting solutions are widely used across:

- Automotive: Suspension arms, housings, brackets, and engine components

- Hydraulics & Pneumatics: Valve bodies, pump casings, and pressure-retaining parts

- Industrial Machinery: Gearboxes, levers, and mechanical linkages

- Electrical Enclosures: Durable, corrosion-resistant housings and panels

Quality Assurance You Can Trust

Evocative Industries maintains a rigorous quality control process throughout the gravity die casting cycle. From melt temperature management to solidification control, we ensure structural integrity, uniformity, and mechanical strength. Each part undergoes dimensional inspection, surface checks, and porosity analysis to meet customer and industry standards.

- ISO 9001:2016 Certified Facility

- Over 10 Years of Die Casting Expertise

- Custom Tooling, Prototyping & Volume Production

- Commitment to Sustainable Manufacturing

- Reliable Delivery and End-to-End Support

Why Choose Evocative Industries?

Looking for a dependable aluminum gravity die casting partner in India?

Trust Evocative Industries to deliver reliable components with repeatable quality. Reach out to us for detailed consultations, pricing, or prototype development.

If your business is seeking trusted aluminium gravity die casting services in Gujarat, India, look no further than Evocative Industries. Our expert team is committed to delivering superior-quality cast components tailored to your application, budget, and timeline.

Ready to transform your project with high-performance aluminium gravity die castings? Contact us today to discuss your requirements. We offer technical consultations, rapid quotations, and ongoing project support for all casting needs – from prototyping and small batch casting to mass production.

Let Evocative Industries be your go-to partner for all aluminium gravity casting solutions. Call or email us now, and experience the benefits of working with Gujarat’s reliable die casting specialists for automotive, EV, defense, electronics, industrial, and appliance parts.